Proper lubrication is key to keeping your Scag zero-turn mower’s deck spindles running smoothly. Over time, grease can break down and metal-on-metal contact can lead to wear. Lubricating the spindles as recommended by Scag will help prevent damage and extend the life of this important mower component.

Table Summarizing Key Lubrication Steps

| Step | Description |

| 1 | Clean spindle housing |

| 2 | Remove zerk fitting |

| 3 | Pump grease into fitting |

| 4 | Reinstall zerk fitting |

| 5 | Wipe away excess grease |

| 6 | Lubricate every 25 hours of operation |

Table of Contents

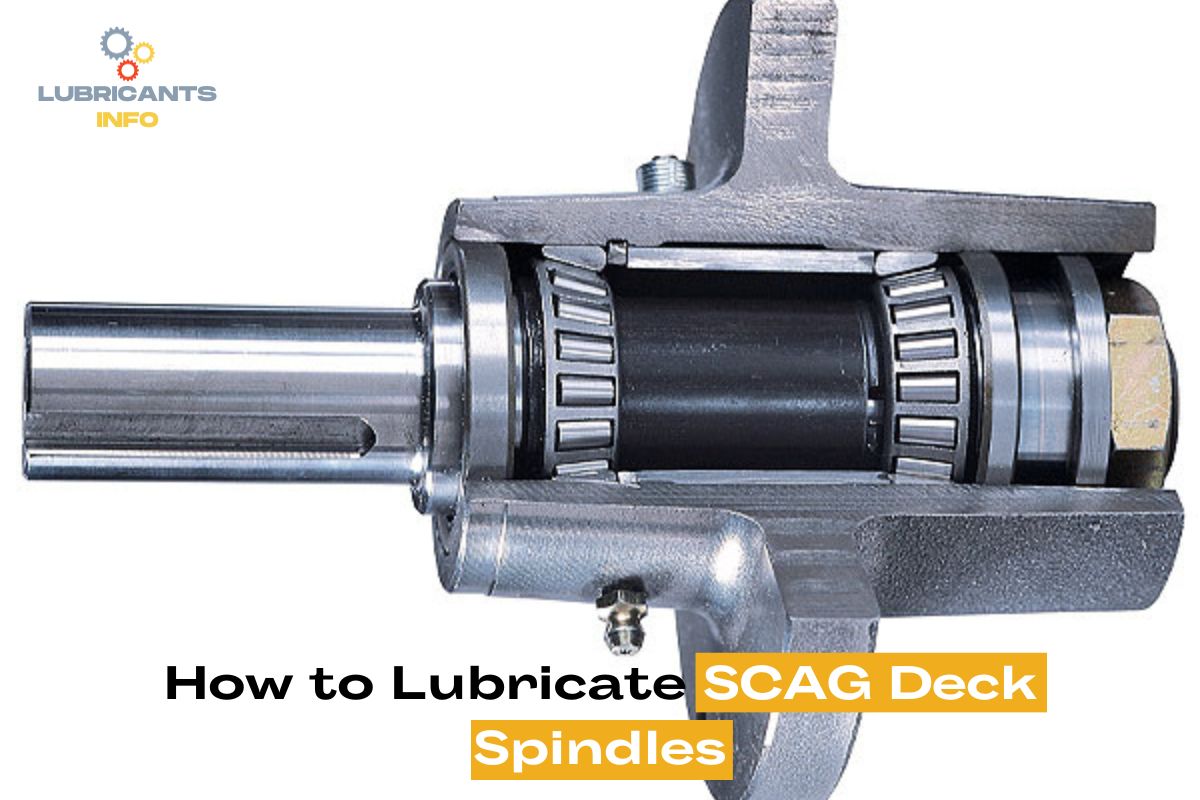

The deck spindles on a Scag zero-turn mower are what the mower blades attach to underneath the deck. When you engage the blades, the spindles spin at high speeds to cut the grass. Like any mechanical component, the spindles need proper lubrication to reduce friction and prevent overheating. By lubricating the spindles regularly, you’ll keep your Scag mower’s deck performing optimally for years to come.

Lubricating the spindles is a relatively simple task that you can perform yourself in your garage or workshop. In this article, we’ll walk through the step-by-step process so you can keep your Scag spindles spinning freely each mowing season. Understanding proper spindle lubrication will save you money on repairs down the road.

When to Lubricate the Spindles

Scag recommends lubricating the deck spindles every 25 hours of mowing operation. This ensures fresh grease is circulating to prevent wear. If you mow an acre or less per week, lubricating at the start and end of each mowing season is sufficient. For heavy commercial use of over 10 acres per week, lubricate monthly.

Excessive noise when engaging the blades or visible metal shavings around the spindles can also indicate it’s time to lubricate. The grease will slowly break down over time, so don’t exceed the 25 hour recommendation between lubrications.

Supplies Needed

Lubricating the spindles requires just a few supplies:

- Grease gun with HD polyurea grease

- Rags for cleaning

- Plastic scraper (optional)

Affiliate Disclosure: We are Amazon associates, and we may earn a commission for qualified purchase

Polyurea grease is formulated to stand up to the demands of high-speed spindle applications. Scag specifies using NLGI #2 polyurea grease. This type of grease has additives to handle heat and resist water contamination.

An inexpensive grease gun loaded with the proper grease is all you need to get started. Having some clean rags and a plastic paint scraper on hand helps with cleanup too.

Suggested Article: How to Lubricate Sawing Machine

Step-by-Step Lubrication Process

Here is the complete process for properly lubricating the spindles on your Scag zero-turn mower:

Step 1 – Clean Spindle Housing

Start by cleaning dirt, grass clippings and other debris from around the spindle grease zerks and housing. Any contaminants can get pushed into the spindle bearings as new grease is pumped in. Use a plastic paint scraper if needed to gently clear off any hardened material.

Step 2 – Remove Zerk Fitting

The zerk fitting is the component on the end of the grease spindles that the grease gun attaches to. Use a rag to get a good grip and unscrew the zerk fitting. This allows old contaminated grease to be purged as new grease is added.

Step 3 – Pump Grease into Fitting

Attach your grease gun to the zerk fitting port and slowly pump fresh polyurea grease into the spindle. Go slowly to allow the old grease to push out. Add about 1-2 ounces of new grease per spindle. Some purging of old grease may occur – wipe this away with a rag.

Step 4 – Reinstall Zerk Fitting

When fresh grease begins to emerge from the spindle, stop pumping. Reinstall the zerk fitting and tighten firmly by hand. You don’t want the fitting to come loose.

Step 5 – Wipe Away Excess Grease

Use a clean rag to wipe away any excess grease around the spindle housing. Try to leave just a light film of grease on the housing to help keep contaminants out. The rag will absorb the purged dirty grease.

And that’s it! Just repeat this process for the remaining deck spindles. With the spindles now freshly lubricated, you can safely put the mower back into service. Just be sure to wipe off any dripping grease on the mower deck or frame. Proper lubrication really is one of the easiest ways to add years of life to your Scag zero-turn mower.

Frequently Asked Questions

How often should the spindles be lubricated?

Scag recommends greasing the deck spindles every 25 hours of operation. This ensures fresh grease is protecting the spindle bearings.

What type of grease should be used?

Use an NLGI #2 polyurea grease for best results. This type of grease can withstand high temperatures and resists water contamination.

How much grease should be added to each spindle?

About 1-2 ounces of grease is sufficient when lubricating each spindle. Go slow with the grease gun to allow old grease to purge out.

Should I remove the deck to lubricate the spindles?

No – the spindles can be lubed with the deck still attached to the mower. Just be sure to wipe up any excess dripping grease.

Can I use regular grease instead of polyurea grease?

It’s best to use the specified polyurea grease, especially for heavy use. Regular grease breaks down faster under high-speed spindle conditions.

Should I replace the zerk fittings when lubricating?

The zerk fittings should be reusable unless damaged or worn out. Just be sure to hand tighten them firmly when reinstalling.

Conclusion

By following this complete guide to lubricating your Scag zero-turn mower deck spindles, you can add years of performance to your investment. Proper lubrication prevents expensive wear and downtime – so don’t put it off. Refer to your Scag manual for specific lubrication recommendations and intervals for your mower model. With just a grease gun, some rags, and a few minutes per spindle, you can keep your Scag mower’s blades spinning like new for season after season of mowing.